For restaurants, bars, and hotels, a reliable ice supply is non-negotiable. This guide delves into the features, installation, and safety protocols for a robust stainless steel commercial ice maker, ensuring you maximize its performance and longevity in a demanding service environment.

Engineering for Commercial Endurance

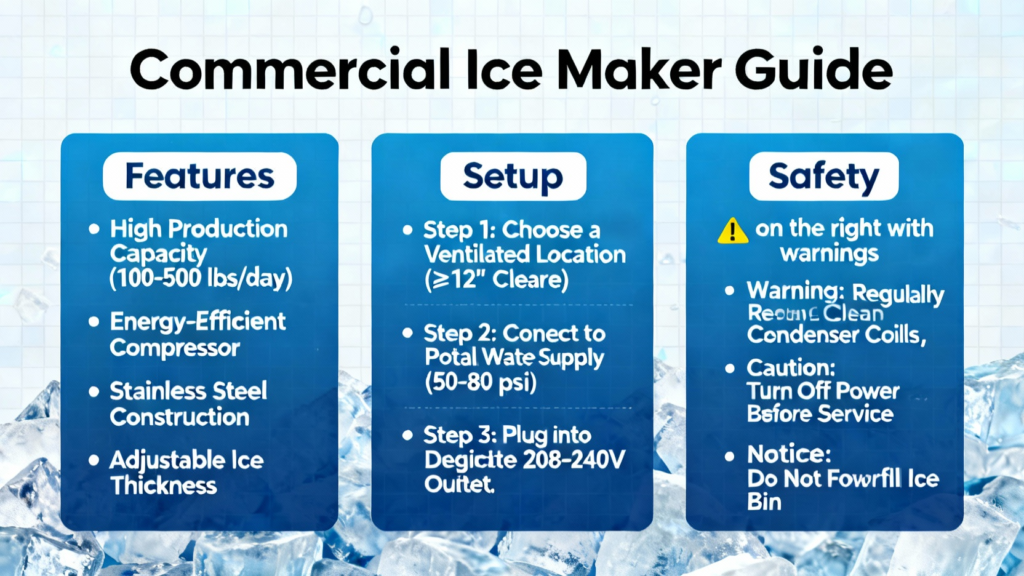

Built with durable stainless steel construction, this ice maker is designed for the rigors of daily commercial use. Its corrosion-resistant exterior is not only hygienic but also withstands constant cleaning. Operating on standard 110V/60Hz power with a 780W draw, it integrates efficiently into most US commercial kitchens. A key feature is its use of R290 (propane) refrigerant, an environmentally friendly option with a low Global Warming Potential (GWP). As noted on Wikipedia, hydrocarbons like R290 are gaining favor as sustainable refrigerants due to their excellent thermodynamic properties and minimal environmental impact compared to traditional HFCs. This unit’s compatibility with climate types SN, N, and ST ensures reliable ice production across varied environmental conditions common in the United States.

For operations requiring robust output, exploring a model like the 26.4 in. 145 lb Capacity Commercial Stainless Steel Ice Maker provides a similar build quality with a different storage capacity to suit specific business needs.

Critical Installation & Setup Requirements

Proper installation is paramount for safety and efficiency. The unit requires a dedicated drinking water supply with a pressure between 14.5-58 psi. Pressure outside this range necessitates a changeover valve to prevent system damage. Furthermore, the ice maker must be positioned with at least 5.9 inches of clearance on all sides for adequate airflow and heat dissipation, a point often emphasized by service technicians in industry discussions on Reddit. The included 70-inch three-prong plug should connect directly to a grounded outlet; using an extension cord is a fire hazard and is strongly discouraged. Upon delivery, the unit must remain upright for 24 hours to allow the compressor oil to settle, a critical step to avoid premature failure.

Operational Safety and Best Practices

Adhering to operational guidelines ensures safety and optimal ice quality. The ice maker must be kept away from heat sources and direct sunlight, as ambient temperature directly influences freeze cycles. It is equipped with a gravity-fed drainage system; the drain pipe outlet must be lower than the machine’s port to prevent wastewater backup. Only potable water should be used, as other liquids can damage the evaporator and contaminate ice. These practices align with general food safety standards, which, as highlighted in food service forums, are essential for preventing cross-contamination and equipment malfunctions. The unit’s Safety Protection Type I classification indicates it is grounded for user protection.

Maintenance for Long-Term Reliability

Consistent maintenance extends the machine’s service life. Regular cleaning of the water filtration system (if equipped) and interior surfaces prevents scale and microbial buildup. Since melting ice in the storage bin creates wastewater, ensuring an unobstructed drain line is crucial to prevent internal flooding. It’s also important to monitor ice production times; significant slowdowns can indicate environmental factors, low water pressure, or the need for descaling. As veteran restaurant owners often advise on hospitality subreddits, a proactive maintenance schedule is far less costly than emergency repairs during peak service hours. Choosing a dependable model, such as the commercial stainless steel ice maker, is the first step in a reliable ice program.

In conclusion, this heavy-duty commercial ice maker represents a significant investment in the operational flow of any food service or hospitality business. Its stainless steel construction and R290 refrigerant system offer a blend of durability and modern environmental responsibility. Success, however, hinges on meticulous attention to the outlined installation prerequisites—from water pressure and electrical safety to proper positioning and initial settling time. Furthermore, ongoing adherence to operational best practices and a committed maintenance routine are non-negotiable for ensuring consistent, hygienic ice production and maximizing the equipment’s lifespan. By understanding and implementing these guidelines, businesses can secure a dependable ice supply, supporting seamless service and customer satisfaction while protecting their investment for years to come. Ultimately, the right equipment, correctly installed and maintained, becomes a cornerstone of daily operations.

This guide is super helpful for understanding the key features and safe setup of a commercial ice maker—exactly what we needed for our new bar!

\}}

This guide is super helpful for understanding the key features and safe setup of a commercial ice maker—exactly what we needed for our new bar!

\}}

This guide really highlights why a reliable commercial ice maker is such a crucial investment for any busy food service operation.

\}}